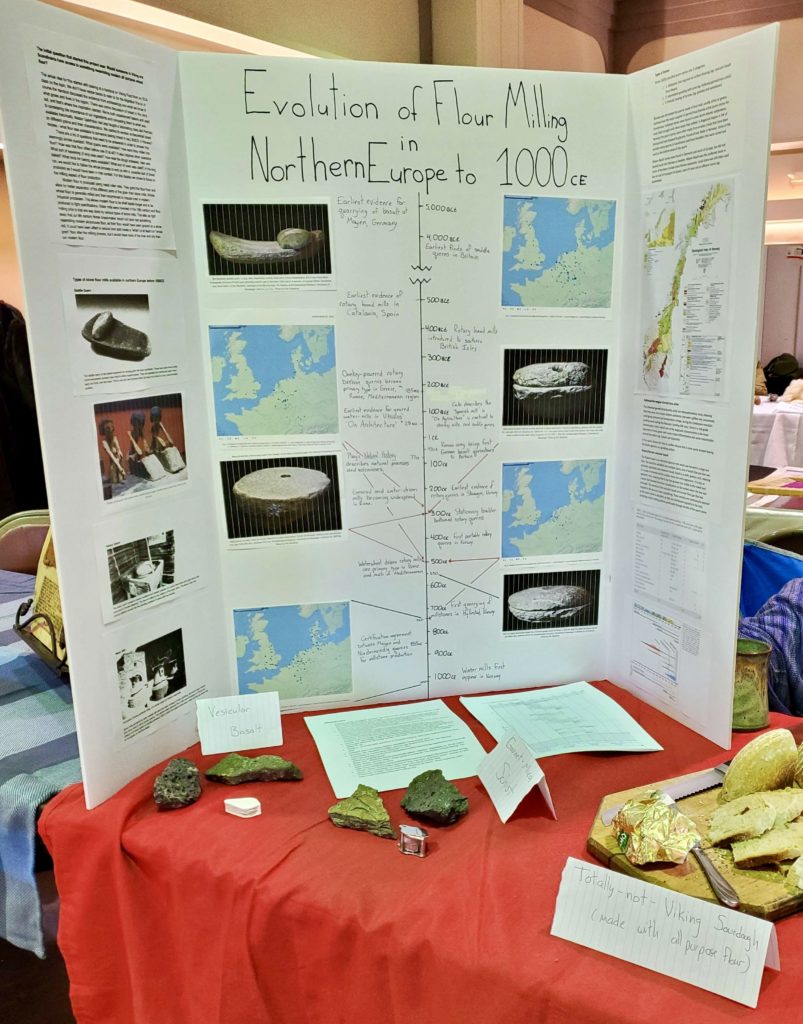

This past Saturday Ragna & I displayed the first stage of our enormous research rabbit hole that started with a seemingly simple question about flour in Viking Age Scandinavia. In order to narrow our focus down to something manageable we chose to display what we’d learned about millstones specifically. Ragna even brought samples of the types of stone most valued for making millstones out of for people to pet! (I brought sourdough bread because of course I did.)

What follows is most of the text of our display.

Introduction

The initial question that started this project was: Would someone in Viking era Scandinavia have access to something resembling modern all purpose wheat flour?

The whole idea for this started with looking at a handout on Viking Food from an SCA class on the topic. We don’t have recipe books to refer to for the Migration Era so of course the handout discussed the evidence from archaeology and what we know of what grows and lives in the region. There was some discussion of bread in the hand out, and that’s where the inspiration started. We’re both experienced bakers and used to considering the importance of our ingredients and comparing them to what was available historically. Master Galefridus had also taught a fascinating class last Pennsic on different grains and their characteristics which provided inspiration as well. We started to wonder: what flour was available to someone baking bread in say, 800CE in Norway?

There are a lot of questions that need to be answered in order to answer this seemingly simple question: What grains were available? How were they milled into flour? How was that flour sifted before use (if at all)? It also inspires other questions: What sort of leavening (if any) was used? How was the dough kneaded, risen and baked? What tools for baking were available? What sort of oven was used? In the long run, we would like to follow the whole process to end up with a possible loaf of bread produced as it would have been in that context. For this display we chose to focus on the milling aspect of flour production.

Modern flour is produced using metal roller mills. They grind the flour finer and allow for better separation of the different parts of the grain than stone mills. Whole wheat flour is generally milled and then recombined to include bran in modern industrial processes. This allows modern flour to be shelf stable longer and to be produced to tight specifications. Roller mills were invented in the 19th century and flour milling prior to that era was done by various types of stone mills. This tells us right away that our 9th century Norse bread-maker would not have had something resembling modern all-purpose flour, as their flour would have been ground on a stone mill. It could have been sifted to reduce bran and create a “white” or at least not “whole grain” flour after the milling process, but it would have more of the bran and oils than our modern flour.

Types of stone flour mills available in northern Europe before 1000CE

Saddle Quern

The saddle quern is the oldest implement for turning grain into flour worldwide. These have been found pretty much everywhere humans have tried to refine husked grains. They are operated by rubbing the upper stone back and forth over the lower. This is not only hard physical labor but has to be done in a very uncomfortable position.

Rotary Quern

The rotary quern comes in several variations but always consists of a round lower stone and upper stone with some kind of handle attached. The flour is milled by the rotation of the upper stone. The stones often had groove patterns carved into the grinding surfaces to assist with the process.

Water Mill

Stone mills powered by water wheels still used the basic concept of rotary grinding, with much larger stones than were used in hand turned querns. The earliest water-powered flour mills were developed in Rome and Greece and were based on donkey-powered mills in which the bottom stone was a cone and the top stone was an hourglass or beehive shape.

Timeline

Note: our timeline includes Greek and Roman developments as there is some belief that milling technology spread from the Roman empire northward in Europe. However, milling technology such as saddle querns appear to have been simultaneously invented all over the world and there is evidence that rotary hand mills spread into Britain and then Scandinavia from Spain independent of Roman influence. This is an area of active historical research and discussion.

- 5000 BCE – Earliest evidence for quarrying of basalt for millstones at Mayen, Germany

- 4000 BCE – Earliest finds of saddle querns in Britain (also found elsewhere in the world at this time)

- 500 BCE – Earliest evidence of rotary hand mills in Catalonia, Spain

- 400 BCE – Rotary hand mills introduced to southern British Isles

- 185 BCE – Donkey-powered rotary beehive querns become primary type of mill in Greece, Rome, Mediterranean region

- 100 BCE – Cato describes the “Spanish mill” in “On Agriculture” in contrast to donkey mills and saddle querns used in Rome, it is believed to be a rotary hand mill

- 25 BCE Earliest evidence for geared water-mills in Vitruvius’ “On Architecture”

- 43 CE – Roman army brings first German basalt quern stones to Britain

- 77 CE – Pliny’s “Natural History” describes natural processes and volcanoes

- 200 CE – Earliest archaeological finds of rotary querns in Scandinavia in Stavanger, Norway

- 200 CE – Geared and water driven mills becoming widespread in Rome

- 300 CE – Finds of stationary boulder-bottomed rotary querns throughout Scandinavia

- 400 CE – First portable rotary querns in Norway

- 500 CE – Waterwheel driven rotary mills are primary type in Rome and much of Mediterranean

- 700 CE – First quarrying of millstones in Hyllestad, Norway

- 855 CE – Certification agreement between Mayen and Niedermendig quarries in Germany for Millstone production

- 1000 CE – Water mills first appear in Norway

Types of Stones Used for Millstones

Strom (1820) classified quern stones into 3 categories:

- Millstones that required no surface dressing (eg. vesicular basalt from Mayen)

- Intermittent grinding with sand (eg.Hyllestad garnet/mica schist)

- Periodic hewing of furrows (eg. granites and sandstones)

Norway was dominated by querns made of local rock, usually schist or gneiss. Hyllestad was the major supplier of garnet/mica/kyanite schist quern stones for Scandinavia. Hyllestad stones were found in some North Atlantic settlements, most likely brought with them when they settled. In Rogaland (region in SW of Norway) the quern stones were often made from erratics (rocks that have been transported and dropped by glaciers, found all over fields in Norway). Some of the earliest rotary querns in Scandinavia used local boulders that were carved and used as the bottom stone of the quern.

Mayen Basalt stones were found in Denmark and much of Europe, but did not extend much into Norway or Sweden. Mayen Basalt was the preferred stone in much of Northern Europe since Roman expansion. Local stone was still often used due to cost of transport of stones, even if it was not as efficient (eg.Sandstone).

Hyllestad/Norwegian Garnet/mica schist

The Hyllestad garnet/mica/kyanite schist are metasedimentary rocks, meaning that they were once ocean bottom sediments that were uplifted and compressed, undergoing pressure and temperature change, during the Caledonian mountain building event during the Paleozoic (starting 500 mya). Schist is a mid-grade metamorphic rock in which one of the diagnostic characteristics is the linear alignment of mica grains with some crystal differentiation and some metamorphic mineral formation (eg. Garnet and staurolite).

In the quern stones the mica is a softer mineral that is more easily abraded leaving the harder garnets as a grinding surface.

Mayen/German vesicular basalt

The Mayen basalt is an extrusive igneous rock which was formed in a large lava flow. The lava flow solidified into multiple layers, one of which (the one that was primarily exploited) was columnar basalt. Basalt is a mafic igneous rock, meaning it is made of minerals which contain more iron and magnesium. It is also an aphanitic rock, meaning that it has fine grained (not visible to the naked eye) crystals that formed from fast crystallization on the surface when the lava was extruded. The vesicles in the vesicular basalt are formed from gas that was trapped in the lava as it was crystallizing. These vesicles are continuously exposed as the quern stone is abraded, as they are distributed regularly in the rock, providing a fresh cutting surface continually through the life of the quern stone.

Bibliography

https://www.bibliography.com/biblio/wQHoBb/

Conclusions / Next Steps

Our first conclusion as mentioned earlier is that modern all-purpose wheat flour is not a good substitute for stone-ground flour. I didn’t mention it on the display but one experimental study found that even the stone-ground flour with the highest rate of extraction had 3 times as much fiber & ash as similar flour ground in a roller mill.

We are continuing our research- at the moment I am looking into sources of information on sifting after flour was ground. We have also found some information on the grains available in Scandinavia and the cooking/baking implements and techniques based on archaeological finds. There’s also some research on finds of bread as a grave good that may give some insight. One of my biggest questions has been about whether leavened bread was even a common food item in Scandinavia at that time? Hopefully some of the archaeological reports we’ve gathered will shed light on that.

We are hoping to convince a friend of ours who works stone to make some quernstones of the right stone to play with. (He seems interested and there is garnet-mica schist in our region.) In the meantime, there are a few historic mills operating in the area that sell stone ground flours of a variety of grains. We are thinking of trying some comparative baking experiments with stone-ground vs roller-mill flour.

We plan to update and expand our display as we learn more. See you this time next year at KASF!

Helena & Ragna

Great job! Fantastic work! I love, love, love your work! Thank you so much for sharing it.